what we do

Capabilities

RTI Offshore is a global provider of oil and gas production process system cleaning and decontamination solutions utilizing patented vapor phase processes and chemistries to partner with clients in support of:

- Facility Turnarounds and Shut Ins

- Planned and Unplanned Maintenance

- Preventative Maintenance

- Decommissioning

Our engineered solutions reduce timelines, minimize HSE exposure, and lower total effluent during de-inventory and cleaning of production process systems (piping, vessels, & tanks), so clients are prepared for turnaround, shut in, and maintenance activities.

Patented Technology

UpTime and OutRigger are applied using the Vaporganic® process. This patented cleaning process has proven to be the fastest, most effective technology for achieving bare-metal clean results.

The Vaporganic® process offers facilities the ability to clean process systems and equipment in less than 12 hours. This technology is ideal for cleaning packed vessels, flare lines, piping, fractionation towers, desalters, fuel gas systems, sour water systems, and other hydrocarbon-service equipment.

UpTime, OutRigger, and the Vaporganic® processes achieve a safe, gas and hydrocarbon-free environment allowing for hot work to proceed immediately upon entry. Waste effluent is significantly reduced from liquid-circulation and other vapor phase cleaning methods and can be processed on the facility in most applications. Application of this technology requires minimal equipment and labor.

How we do it:

Exceptional People

We leverage the knowledge and expertise of over 20 years of industry experience in refinery process system deinventory and cleaning as part of turnarounds. We know firsthand the tasks and challenges of a cleaning project, and we apply our experience to each step of the process, from confirming the project scope to developing chemical cleaning plans for execution.

Superior Chemistries

Utililizing the powerful combination of our patented Vaporganic® process and UpTime chemical formulation, we’re able to effectively clean process systems — removing all petroleum-based hydrocarbons and delivering zero benzene, H2S and LEL. Our innovative technologies also help reduce effluent and discharge waste.

Enhanced Services

We have a complete line of mechanical equipment required to deliver our Vaporganic® cleaning process, including: pumps, piping and valves, steam hoses, knock-out drums, and drain headers. Much of this equipment has been custom-designed to deliver our process efficiency.

INNOVATIVE TECHNOLOGY

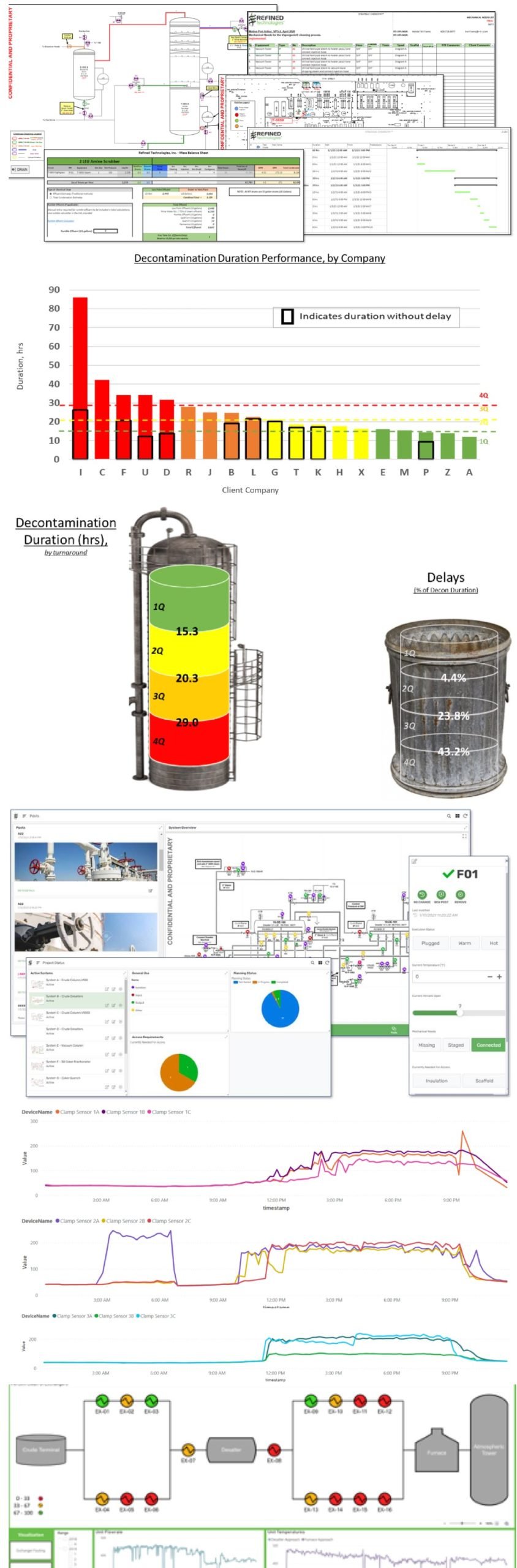

From detailed project planning to execution, we use a revolutionary approach to unit shutdown and decontamination. We continue to push the envelope of innovation and best practices.

OUR PROCESS

OUR CONSULTING APPROACH ENSURES SUPERIOR EXECUTION.

WE MAKE A COMPLICATED PROCESS PREDICTABLE. HERE’S HOW:

01. DETAILED PLANNING

Well in advance of the turnaround, RTI Offshore personnel work with client personnel to develop detailed cleaning plans integrated with the plant clearing plans. Manuals for the project are prepared to control the entire process from start to finish.

02. MOBILIZATION

Our Operations Managers walk through the project with unit operations personnel well in advance of the turnaround. During these walkthroughs, mechanical needs are reviewed, punch lists are prepared and all issues that may otherwise jeopardize the project success are resolved.

03. ON-SITE TRAINING

After the cleaning plans have been reviewed and approved by all stakeholders, we conduct detailed on-site training for all personnel impacted by the cleaning. This training intensive ensures that the cleaning is carried out in the most safe, effective and expeditious manner.

04. EXECUTION

Handoffs create room for error. With RTI Offshore, the team that plans is the team that executes. 24-7 on-the-floor expertise ensures operational excellence with minimal shutdown time and maximum results.

05. FOLLOW UP

After safing the equipment, RTI Offshore does not consider the job done. We run robust data analytics to review standards and deliver ESG metrics. We also prepare a “Lessons Learned” document that includes copious notes taken during the project with suggestions for future projects. This document is reviewed on-site with client management and used to support our commitment to continuous improvement.

06. FEEDBACK

As part of our efforts to continually evaluate our effectiveness and improve our performance, we ask clients to complete a short review of our work. This feedback is reviewed by top management and is a critical element in our continuous improvement process.

“The level of assistance, communication and effectiveness

made them as if they were part of the team.” — BP

We Believe Eternal Purpose Fuels Excellence

At RTI Offshore, we believe operating with an eternal purpose fuels excellence. This belief guides our enterprise and provides daily inspiration. We believe our work matters because we are motivated by an eternal purpose that helps us strive for excellence. The work we deliver and the care we provide for both Artisans and clients has lasting significance.