Effective Equipment Decontamination

Reduce Downtime with RTI OFFSHORE

OutRigger and UpTime are fully organic solvent-based chemistries customized to dissolve and mobilize organic solids. Using a proven and predictable process for removing hydrocarbons from processing equipment ensures minimal downtime during the shutdown and equipment preparation window. Getting your scope of work to RFM (Ready for Maintenance) status in a timely manner ensures the highest level of production.

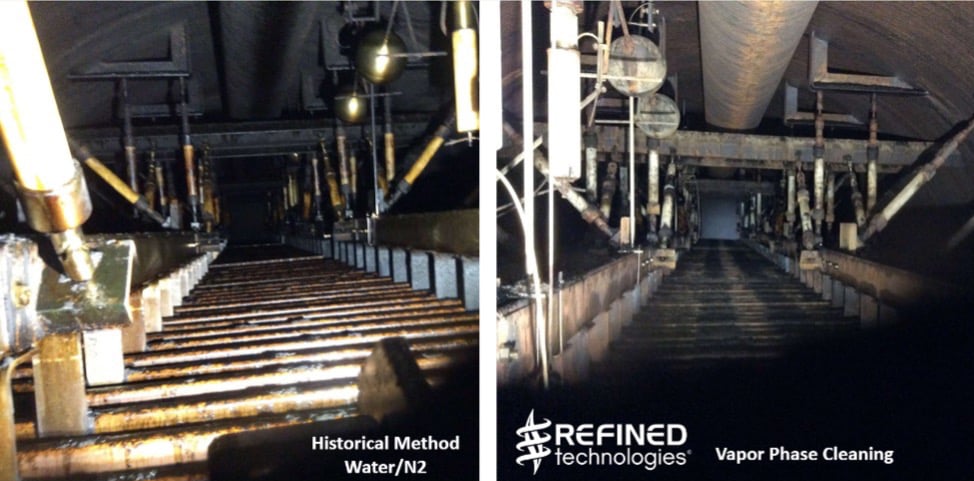

Vapor phase cleaning versus legacy water flushing and nitrogen purging

Utilizing an innovative and efficient solvency-based cleaning mechanism in a steam environment, versus the traditional mechanical mechanisms of water flushing and nitrogen purging, increases speed, efficiency, and cleaning predictability.

Redefining equipment cleanliness

Equipment cleanliness can be defined in many ways, but ideal cleanliness is defined as completely hydrocarbon free with only dry/loose solids left behind. Traditional methods typically displace bulk hydrocarbons via water flushing and flooding and then utilize nitrogen purging to ensure the equipment vapor space is free of LEL and other hazardous gases. Vapor phase cleaning utilizing UpTime and OutRigger performs both objectives in a single step with an exponentially higher degree of cleanliness. The expected outcome is equipment that is completely free of hydrocarbon contaminants.

Eliminating lengthy mechanical cleaning

Additional mechanical cleaning after the equipment preparation window consumes large amounts of time necessary for equipment maintenance and repair. Utilizing a preparation process that can generate repeatable results with a high degree of equipment cleanliness allows for shorter downtime windows and/or more available time for equipment repairs.

.png?width=240&height=192&name=UpTime%20logo%20(2).png)